|

Teddy

Evolves (cont.)

July 2002

Stanley

Block sells stuffing machines and bear supplies from his California-based

Teddy Bear Stuffers. Business is so hot, he says, “I am literally

unable to keep up with demand.” Stanley

Block sells stuffing machines and bear supplies from his California-based

Teddy Bear Stuffers. Business is so hot, he says, “I am literally

unable to keep up with demand.”

Jerry

McLean, who sells the train- and house-styled stuffers, says tremendous

markets still exist for the make-your-own-bear concept. Both talk

of “customers” or vendors (they aren’t franchisees)

who have grossed over $100,000 in sales last November and December

alone.

Another

bear vendor who McLean supplies (who wishes to not be named for

competitive reasons), will probably make $600,000 stuffing and selling

bears at various universities this year. McLean routinely airfreights

thousands of shirts to the vendor’s silkscreener, who prepares

them for the next college on the travel itinerary.

Echoing

Block, McLean says, “We can’t keep product in for this

guy.”

Stuffing It Yourself

In

1985, Merrilee Woods of the Basic Brown Bear Co. in San Francisco

noticed what a draw the stuffing process was, and “stumbled

on the ‘stuff-it-yourself’ idea.” They’ve set

up mini-factories in a few other locations, including the Mall of

America, and the original San Francisco location entertains 65,000

visiting children a year. In

1985, Merrilee Woods of the Basic Brown Bear Co. in San Francisco

noticed what a draw the stuffing process was, and “stumbled

on the ‘stuff-it-yourself’ idea.” They’ve set

up mini-factories in a few other locations, including the Mall of

America, and the original San Francisco location entertains 65,000

visiting children a year.

Build-A

Bear is another major player in the ‘stuff it yourself’

enterprise, and many Americans are already familiar with their inline

mall stores. A company representative says 2002 will see over 100

Build-A-Bear stores open in malls and resort locations. Founded

in 1997 by Maxine Clark, a former president of Payless Shoe Source,

Build-A-Bear got the jump on mall-based bear stuffing, and highly

promotes its locations for birthday parties and other children’s

events.

Jerry

McLean caught wind of the concept while on vacation in Mackinaw

City Michigan, also about five years ago, after he’d retired

as CEO and president of the Panama Jack Suncare Company. He kyboshed

the notion of establishing a chain of stores at the time, but re-approached

stuff-your-own idea in May of last year. This time he decided that

helping others establish stores and amusement park booths was the

way to go.

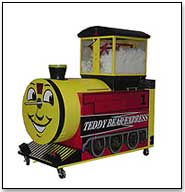

Bear Factory's Train Stuffer |

Putting

his engineering background to use, McLean worked with Fiber Products

Northwest to design the fun-looking train motif stuffers. He established

about 60 vendor accounts his first year, but the weight of the train

design-430 pounds-made portability a concern to potential new vendors.

Stuffing

machines have been around for about 50 years, according to McLean,

and the current design originated out of a device that filled pillows.

The problem he faced was the compressor; bulky and heavy, it would

have to go.

After a trip back to the drawing board the Bear House was built.

At 212 pounds it’s much easier to lug, making it the latest

thing in the stuffing business.

What

the Market Will Bear

Where

are we on the make-it-yourself curve, and when will this bear bubble

burst… (cont.)

Previous

| Next

A Stuff-Your-Own

Retailer tells his story: Click

Here...

|